Protective Clothing X-ray Testing

X-ray protective clothing, in particular aprons, is widely used to reduce the radiation dose received by personnel during X-ray examinations. Currently, to control the properties of protective clothing, medical X-ray installations or a method for determining the weakening properties of X-ray protective materials are often used.

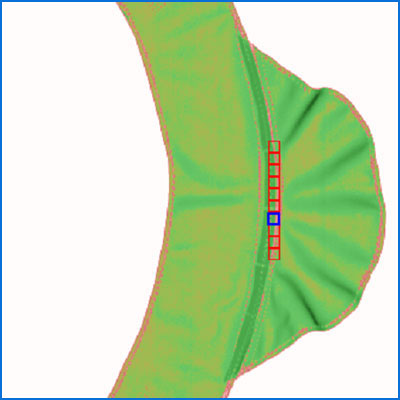

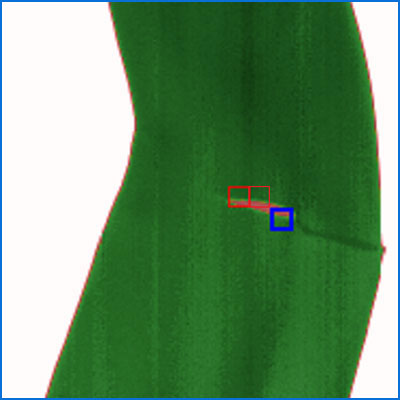

The design of the X-ray flaw detection system intended for testing such protective clothing and materials. Innovative algorithms of processing the resulting images, developed by LINEV Group specialists make it possible to obtain a complete information about the homogeneity of the test materials, which, in addition to the standard procedure for determining the inhomogeneity parameter, opens up the possibility of introducing more capacious and informative characteristics.

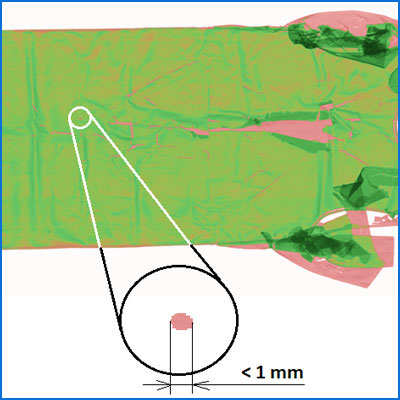

The indicated disadvantages of the traditional method flow detection are largely eliminated in the [LV] FLOWD. Its functioning is based on X-ray scanning with the use of a narrow fan beam of radiation and a linear dual-energy detector. Scanning large surfaces of an object with [LV] FLOWD allows observing any minor damage to the protective layer over the entire area of the object being inspected, as well as detecting and characterizing all larger ones with a 100% probability.

In addition to this obvious advantage, [LV] FLOWD flaw detector implements a new high-precision method for determining the attenuating properties of materials, which has a number of advantages over the currently used one and may well form the basis for a new standard for determining the weakening properties of X-ray protective clothing.

The scanning and image processing procedures of [LV] FLOWD are based on the use of array detectors eliminating all serious problems associated with the use of ionization chambers. In particular, when using array detectors, there is no problem of the dependence of the detector response on the size of the irradiated area. In addition, taking into account the direction of radiation at each point of the detector during signal processing during detector calibration and measurements removes the requirement for a low beam divergence and eliminates its influence on the measurement results.

These advantages of the [LV] FLOWD flaw detector make it possible to count not only on its widespread use for testing X-ray protective clothing, but also open up the possibility of introducing new, simple and more accurate tool for checking the quality of X-ray protective materials and clothing.